What is Neonatal Incubator

Neonatal incubators or baby incubators are medical devices that were created to provide a controlled environment for newborns that require special care. An environment is generated where different variables important for the development of newborns are controlled, such as temperature, humidity, and oxygen.

|

| Baby Incubator |

The incubators consist of a transparent cover that allows isolating the patient without losing visual contact with the baby. In addition, NICU team has access to the newborn through gates that allow you to assist the baby with limiting the introduction of cold air in the incubator.

The baby incubator's main components are a patient compartment, the cover, the mattress, the platform, the rolling base, and the control module, in which are all the parameters like temperature, humidity, and oxygen are controlled.

Commercially, the types of neonatal incubators differ in shape and form in which they are constructed or in their control and heating systems. However, all of them generally include the following basic components:

- Hood or cover made of transparent material, inside which the newborn is placed and where a controlled microclimate is generated.

- Mattress; Here the patient is placed; the mattress cover must be made of a low porosity material to facilitate cleaning and sterilization.

- Trolly; which is the structure that serves as a base and support for the Hood and its control systems. In general, this structure is incorporated with all the components that make up the incubator and allows its mobilization.

- The temperature control module, where you can select the operating mode of the incubator, and temperature set limits that the incubator is going to operate on.

- Humidifier. that usually includes water tanks to control the relative humidity of the environment.

- Port or entrance for oxygen supply.

- Block or control of alarms. Alarms pre-set at the factory or adjustable by the operator. These are audible and visible and are intended to increase patient safety during treatment.

The alarms commonly found in the incubator models are:

- Air temperature Alarm: In relation to the temperature established by the health personnel; the alarm can be activated when the 'high/low' temperature limits sets are reached.

- Skin temperature alarm: In relation to the temperature set by the operator, the high or low-temperature alarm of the skin for the newborn can be activated.

- Sensor Alar:. It is activated in case of failure of the patient's temperature sensor.

- Air intake filters. This alarm is activated when there is resistance at the entrance to the outside airflow to the incubator.

- The concentration of O2. Detects the variation of oxygen concentration inside the incubator.

PREVENTIVE MAINTENANCE

Routinely inspect the patient compartment for signs of rupture and replace the assemblies before operating the incubator. In addition, you must ensure that all connections to the incubator are disconnected, especially with the oxygen supply when performing cleaning and maintenance procedures; there is a risk of fire when performing maintenance procedures in spaces containing supplemental oxygen.

TESTING BABY INCUBATOR TEMPERATURE SENSORS

It is the most important step in the PPM procedure, as this step will make sure that the baby incubator set temperature is met and that the baby inside is getting the exact same amount of warmth the is determined by the doctor.

The procedure for testing the temperature sensors in baby incubators is a standard one and is found in the IEC 60601-2-19 which is basically composed of 6 steps and is as follows:

- The room temperature should be between 21 to 26 C

- Incubator temperature must be adjusted to 11 degrees Celsius above room temperature. The temperature must be reached within the limits specified by the manufacturer and tolerance could be around 20%.

- Now you have to set the temperature to 2 degrees and wait for temperature stabilization then you have to make sure that the temperature is stable for one hour with a tolerance of fewer than 1 degrees. The same procedure should be followed but now the set temperature to 36 degrees.

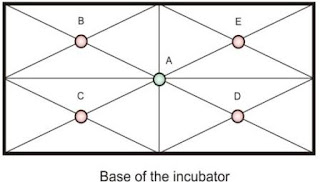

|

| Temperature Sensors Distribution |

- Now the Sensors distributed on points (A, B, C, D, and E) should measure a temperature variation of fewer than 0.8 degrees than the average temperature. Also, the measured temperature should vary with a maximum of 1.5 degrees with the incubator sensor.

- Humidity should vary by less than 10% of that measured by the incubator sensors.

TESTING BABY INCUBATOR WEIGHING SCALE

This is usually an easy step, all you have to do is have a fixed weight usually 5 kg or 3 kg based on a manual recommendation.

TESTING BABY INCUBATOR OXYGEN SENSORS

In most incubators, it is recommended to replace the oxygen sensor every year to ensure best oxygen level readings, and there is a need to make sure that the oxygen sensor is properly calibrated this is done by having a calibrated oxygen analyzer and pure oxygen supply (100% oxygen gas cylinder).CAUTION: It is very important to make sure that the oxygen sensor calibrated properly as that is related to baby safety and might pose high risks to the baby's health.

TESTING BABY INCUBATOR CURRENT LEAKAGE

Since the baby will be inside the infant incubator almost all the time and a skin sensor might be in contact with the baby, then it is very import to make sure that current leakage is at its minimal levels as baby skin resistance is very low thus allowing for current to pass through her body. So it is crucial to check for current leakage and make sure to look for the manufacturer's recommendations on these levels.

You will need a calibrated leakage tester to test for current leakage, most incubators do not allow for a leakage above 300 micro-ampers, you should know the resistance of the leakage tester as it influences the current measured. Also, this should be specified in the manual.

Cleaning Baby incubator

The baby should be removed from the incubator before cleaning and recommended when the baby is discharged, or at least once a week the incubator is cleaned and disinfected completely.

Cleaning and disinfection should be done when used first. The most effective way to clean is to disassemble first, and then group the parts and assemblies into categories according to the required cleaning method. The rechargeable battery should be replaced every three years.

Usually, most of the cleaning done for the outer parts can be done by the staff in the NICU, but the cleaning of internal parts is mainly the task that a biomedical technician is going to do. NICU staff are not familiar with the internal parts of the incubator and thus will be unable to perform the needed tasks.

Cleaning and disinfection should be done when used first. The most effective way to clean is to disassemble first, and then group the parts and assemblies into categories according to the required cleaning method. The rechargeable battery should be replaced every three years.

Usually, most of the cleaning done for the outer parts can be done by the staff in the NICU, but the cleaning of internal parts is mainly the task that a biomedical technician is going to do. NICU staff are not familiar with the internal parts of the incubator and thus will be unable to perform the needed tasks.

Disassembly if Infant incubator

To perform routine cleaning, it is not necessary to separate the bell assembly from the support.

- Turn off the main power switch and remove the power cord. Remove the access door sleeves, seals, sleeves of the iris inlet port, and flexible intravenous port.

- Disconnect the cables from the Sensor Module and remove the I.V pole. Open the hood latches, remove the hood and the inner wall. Before lifting the incubator cover to clean it, make sure that all mounted accessories have been removed to avoid interference with the raised cover.

- Slide the mattress tray and remove the moisture sponge.

- Pull the blocking of the main platform connection to remove the main platform.

- Loosen the two screws on the air filter cover and remove the air filter.

CLEANING AGENTS THAT CAN BE USED IN BABY INCUBATOR

Use intermediate level detergents or disinfectants, but only after the incubator is empty and dismantled. Follow the manufacturing instructions for the cleaning agent. After removing all solid waste and contaminants from the disassembled parts, clean them.

The recommended disinfectants include:

- 0.2-0.5% aqueous solution of benzalkonium chloride

- 0.2-0.5% aqueous solution of benzethonium chloride

- 0.1-0.5% aqueous solution of chlorhexidine

Never use the above agents undiluted. Do not use any abrasive cloth, cleaner, alcohol, acetone or another solvent for cleaning and disinfection. Do not use the autoclave.

CLEANING SKIN TEMPERATURE PROBE IN THE INCUBATOR

Use a registered disinfectant to clean all surfaces, and then dry with a clean cloth or paper towel. Do not immerse the probe in the disinfectant as this might affect the probe's ability to detect temperature.

CLEANING PORTS OF ACCESS TO TUBES, DOOR OF ACCESS DOORS AND GASKETS

Place them in a suitable container filled with disinfectant. Allow them to soak as recommended by the manufacturer of the cleaning solution, then remove them and wash them with distilled water and dry them completely with a clean cloth or paper towel.

CLEANING SENSOR MODULE

Remove all cables connected to sensors. Also, remove the connector from the relay box. Pull the sensor module out of the hood and lift it up.

In some models, the module cannot be removed. Clean the sensor module by pulling firmly on a soft cloth moistened with a disinfectant solution.

CLEANING HOOD AND INTERIOR WALLS

Use a registered detergent to thoroughly clean all surfaces of the hood, including holes, slits, all access doors, and the access panel. Be sure to clean all holes and crevices, and then dry with a clean cloth or paper towel.

Do not use alcohol to clean as it may cause cracking of the clear acrylic hood. Do not expose the bell assembly to the direct radiation of germicidal lamps. Ultraviolet radiation from this source can cause cracking of the joints, discoloration of the paint, and cracking of the transparent acrylic hood.

CLEANING MATTRESS, HUMIDITY SPONGE, MATTRESS TRAY AND MAIN COVER

Use a registered detergent to thoroughly clean all surfaces, including crevices; then dry with a clean cloth or paper towel. Remove the moisture sponge and the mattress cover to wash with a registered detergent, then wash with clean water and dry in the sunlight.

When cleaning the incubator housing, care must be taken to avoid the entry of liquids. Remove any accumulation of lint on the heater radiator and fan impeller.

Use a registered detergent or disinfectant to thoroughly clean all surfaces, and then dry with a clean cloth or paper towel, and then take special care when cleaning the fan, heater, and surface of the air temperature sensor.

Then, dry them with a clean cloth. Some chemical cleaning agents can be conductive and/or leave a residue that can allow the accumulation of dust or dirt that can be conductive.

Do not allow cleaning agents to come into contact with electrical components.

Do not spray cleaning solutions on any of these surfaces. If the fan impeller is not cleaned, enough fluff may accumulate to reduce airflow, which will affect the temperature control and cause a high concentration of carbon dioxide.

CLEANING MICROFILTER OF AIR ADMISSION

You should not try to clean the microfilter. Replace it if it is visibly dirty or has been placed for more than 2 months. Before installing a new filter, clean the Microfilter Cover with the detergent/disinfectant. A dirty inlet filter can affect oxygen concentration and/or cause carbon dioxide buildup. Make sure that the filter is checked routinely according to local conditions.

CLEANING THE TROLLEY

Use a disinfectant-detergent to clean all surfaces of the trolley and dry with a clean cloth or paper towel. Do not lubricate the mattress tray plug with lubricating oil or other fuels.

CLEANING THE FAN

Pull up and remove the fan. Soak and clean in a disinfectant solution. Dust accumulation on the fan might lead to fan failure in the future.

CLEANING CONDITIONING CHAMBER

The conditioning chamber will be visible when all the components mentioned above are eliminated. Push the heater away from you and clean the inside of the conditioning chamber thoroughly with a soft cloth moistened with a disinfectant solution.

REASSEMBLY AFTER CLEANING

Examine all clean components to detect cracks or breaks before reassembling them in the incubator. Strong cleaning agents can crack some of the plastics used in the patient compartment.

- Place the main platform, the mattress tray, the mattress, and the hood.

- Check the mattress visually and physically, looking for holes or cuts that allow the entry of fluids into the internal foam. If the mattress is damaged, it must be replaced.

- Install the gasket and the access door sleeve.

- If the incubator needs to be sterilized with gas, wait until after the sterilization to install the new cuffs. In the event that the access door gasket is too hard and difficult to install, place it in warm water before installation.

- Some incubator models include phototherapy lamps (halogen lamps) these should be replaced by a complete set of lamps by trained service personnel after 1000 hours of operation or if one or more phototherapy lamps fail.

Battery Testing in an Infant Incubator

Some incubators have internal batteries that are used to keep the incubator working even if there was a power failure. Some incubators have the ability to operate for longer than 2 hours on the internal battery.

Others allow the connection of external batteries of either 12 volts or 24 volts, thus allowing for more working hours to be achieved. So based on the manual you need to make sure that the battery is working properly and can achieve an acceptable working time that is set by the manufacturer. If this period of operation cannot be achieved that replacing the battery is recommended.

Some manufacturers recommend replacing the batteries every 1-2 years based on the load of work where the incubator is working on battery support.

Conclusion

Finally, it is crucial to make sure the baby incubators are taken care of and are working at the best working conditions possible as such devices are the lifeline of a premature baby that would not be able to survive on his own if temperature or humidity was not controlled.

So did we miss anything related to applying preventive maintenance to an Infant incubator? Do you have any ideas that could be useful to others please share them with us in the comment section below!

No comments:

Post a Comment

We are happy that you want to comment, please note that your comment will be reviewed first before it is published.

If you like the article! You can share it with your friends and colleagues by pressing at social media buttons provided to the left of the page.

NO word verification or sign up is required!